- HOME

- ABOUT US

-

PRODUCTS

- Water Pumps

- Surface Pumps

- Waste Water Pumps

- Blowhole Pumps

- Water Meters

- All Types Meters

- Accessories

- All Accessories

- CONTACT

-

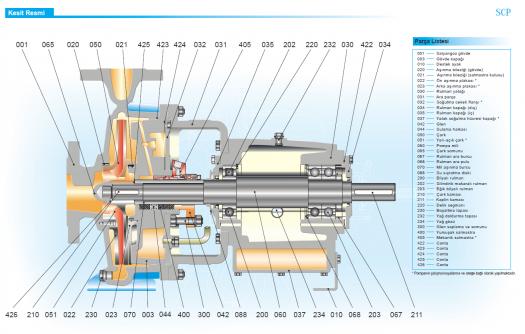

SCP Type pumps are suitable for clean or slighUy contaminated liquids with low viscosity.

Horizontal, single stage, radially split voluts casing type, end suction centrifugal pumps with closed or semi-open impeller.

ln addition to 26 basic sizes conforming with EN 22858 I ISO 2858, there are 10 additional sizes. Dimensions of additional sizes may differ from other suppliers.

Suction and discharge flanges conforming to ISO 7005/PN16.

Due to the back-pull-out design, the complete bearing assembly including impeller and shaft can be dismantled without removing the volute casing from the piping system.

All impellers are dynamically balanced according to ISO 1940 class 6.3.

Axial thrust is balanced in closed impeller by wear ring I balance hole sysrem and in semi-open impeller by back ribs.

Heavy duty shaft not in contact with the medium handled (dry shaft).

For casing sealing, confined gaskets are used to prevent blow-out under pressure.

Depending on request or requirement, pumps with soft packing or single, double and cartridge type mechanical seals can be supplied.

External seal cooling system may be used if required.

Pump shaft Is supported by oil lubricated, long-life, heavy duty rolling bearings. On the coupling side two angular contact ball bearings and on impeller side cylindrical roller bearing or ball bearing is used.

Metal thrower, in addition to oil seals, is used to prevent leakage into the bearings.

High capacity oil reservoir decreases oil temperature thus increases bearing life.

Cooling chamber in the bearing bracket for oil oooling.

Cast Iron bearing bracket provides a solid support for the pump shaft and increases bearing life.

Chemical Industries

Food and Beverage Industries

Heating Cooling Conditioning

Iron and Steel Industries

Oil Industries

Paper and Paper Paste Industries

Power Plants